See Additional Content Below

beamqlaser@gmail.com | info@beamq.com Chat box at bottom

Featured Products

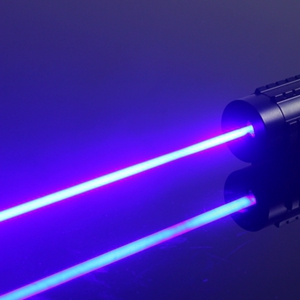

Real Output Power 5W 5000mW Blue Laser Torch Adjustable Focus Kaleidoscope

$259.00 $199.00Save: 23% off

Portable Laser Dazzler Law Enforcement and Self Defense High Power Lasers for Sale

$490.00 $490.00Save: 0% off

Most Powerful 300-500mW Green Laser Rifle Sight Long Range Laser for AR15

$159.00 $129.00Save: 19% off

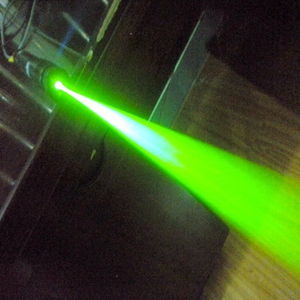

High Power Green Laser Dazzler Non-lethal Dazzler Weapon Eye Safe 532nm Green Beam

$560.00 $369.00Save: 34% off

465nm Sky Blue Laser Pointers Torch Output Power 3W 3000mW Water Proof Burning

$599.00 $199.00Save: 67% off

15W Blue Laser Torch Pointers Flashlight Highest Real 15,000mW Output Power

$498.00 $490.00Save: 2% off

Monthly Specials For April

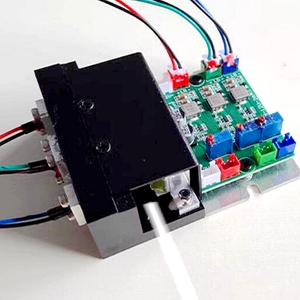

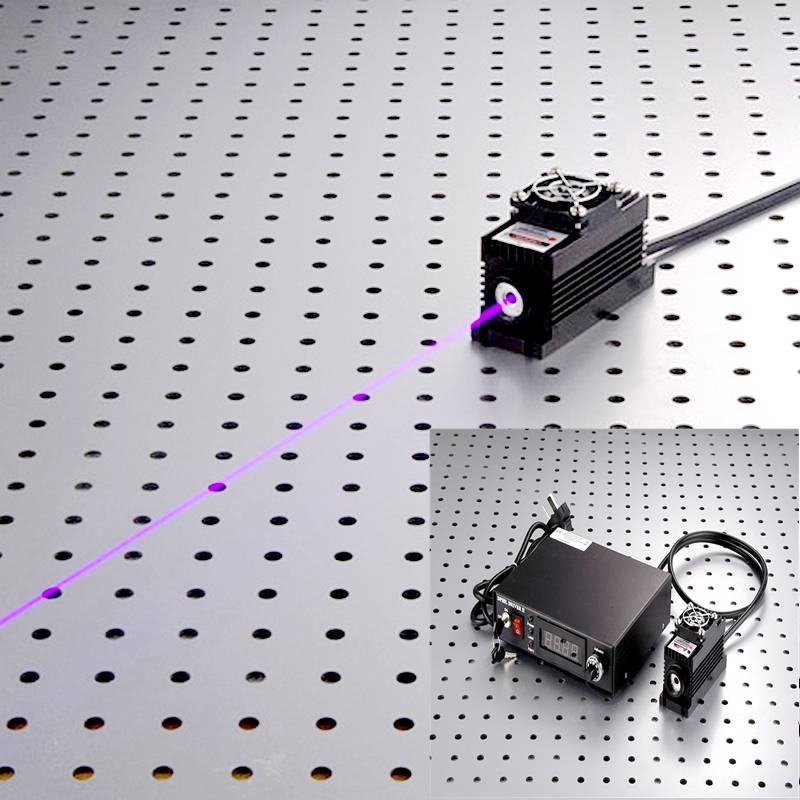

Collimated Gaussian Beam 405nm Solid State Laser Source with TEC cooled Analog TTL modulation

$690.00 $679.00Save: 2% off

High Power Green Laser Dazzler Non-lethal Dazzler Weapon Eye Safe 532nm Green Beam

$560.00 $369.00Save: 34% off